PROCESS

About

We have created a series of lighting fixtures which are mostly intended to be lighting for interior spaces, including table lighting, dresser lighting and the like. The lighting fixtures are made of wood, and were laser cut. While the covers, "lampshades" were produced by 3D printing.

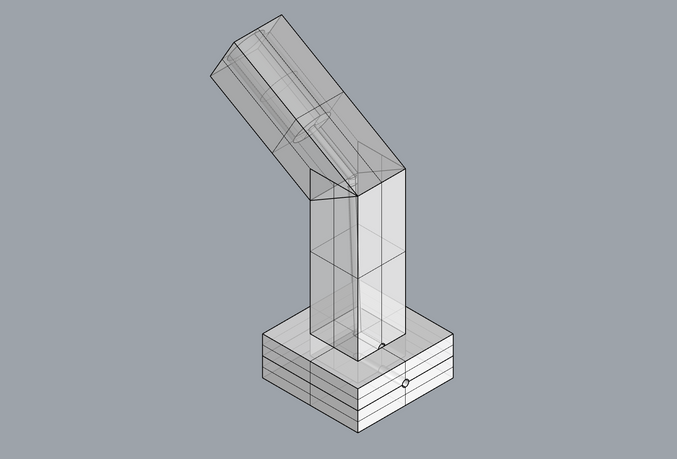

rahino model

The rhino model of the lamp had to be a careful design taking into account several important things.the lamp wire passing through it And the slag lamp that will come out from the other side

the lamp house

The model of the lamp head is a creative and special part of the project. We designed the lamp heads so that each one has a unique pattern.

In addition, you can replace the head of the lamp and get several options with the light.

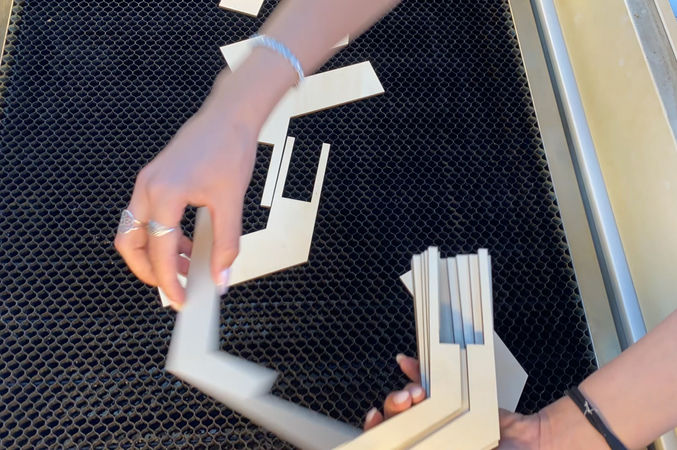

lazer cutting

We cut the leg of the lamp in the lazer machine. we spread it into 13 vertical parts and thus preserved the inner holes where the wire of the lamp would pass.

After that we assembled all the parts together, glued them and held the cores. And finally we chose to put everything in black greed.

Printing the lamp house

We printed five lamp houses with the 3D printers.